- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

EP-DR16493

ISO9001, RoHS, Reach, FDA, En71

Metal

Film Forming Matter

Conversion Type

120-150%

120-150um

2h

0 Grade

50kg/Cm

WONDER

20kg/CTN

39.5*30*35

Guangdong, China

3907999990

| Product Details | |

| Type | Candy Nano Chrome Rose Red Powder Coating For Steel Hanger |

| Colors | Chrome Rose Red |

| Surface Finish | Smooth |

| Gloss level | 120-150% |

| Particle Size | Average 32-42μm |

| Specific Gravity | 1.2-1.7g per cubic meter |

| Coverage | 8-10 square meters per Kg at 30-90 μm film thickness |

| film thickness | 120-150um Two Layers |

| Application Recommendation | |

| Application Voltage | 40-60 KV |

| Gun to Component Distance | 15-30CM |

| Curing Temperature | 200ºC x 10min |

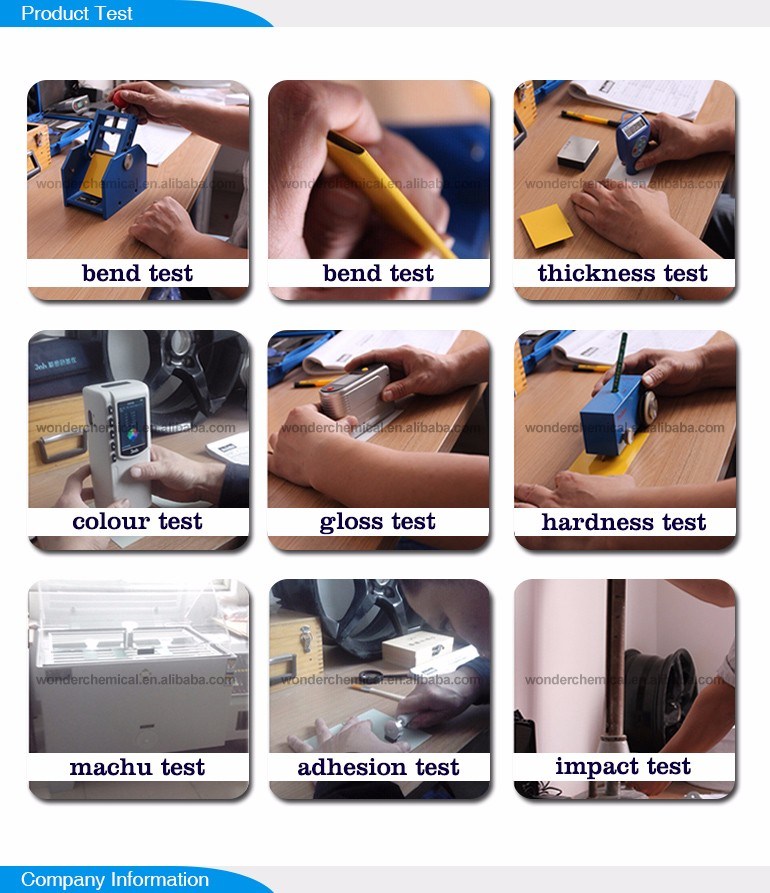

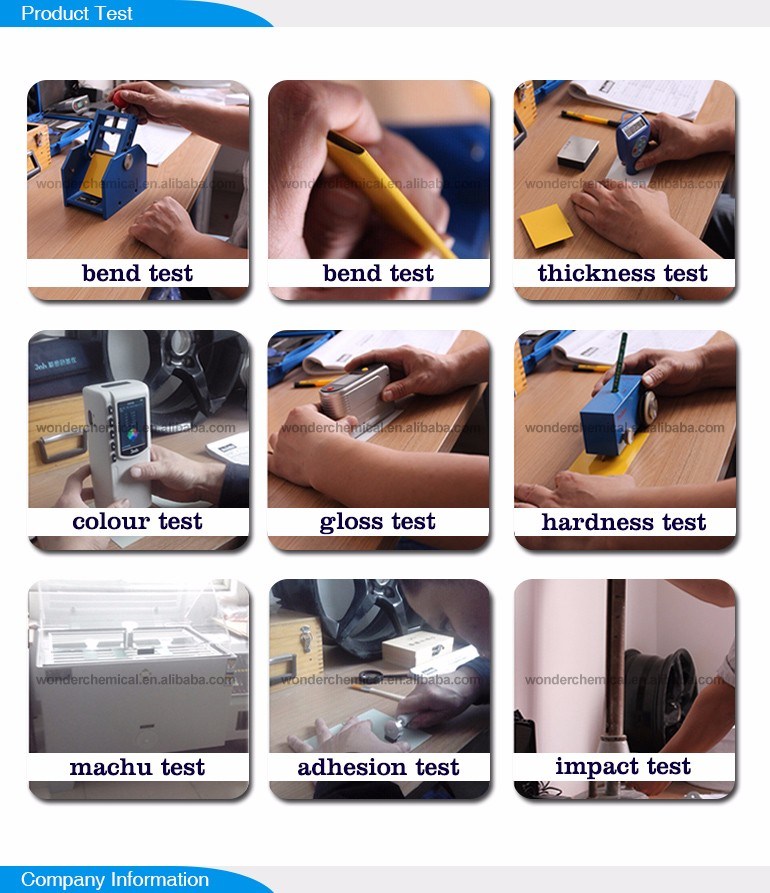

| Powder coated Film Mechanical Properties | |

| Adhesion | Cross-cut(2mm),no loss of adhesion |

| Impact Resistance | Direct impact 50kg/cm |

| Pencil Hardness | 2H |

| Cupping Test | 6mm Mandrel |

| Bending Test | 5mm |

| Powder Coated Film Chemical Resistance | |

| Salt Spray Test | 5% NaCl Solution for 500 hours - No change |

| Acid Resistance | 5% HCL for 48 hours dip test - No change |

| Alkali Resistance | 5% NaOH for 48 hours dip test - No change |

| Storage Stability | |

| Store in ventilated, dry, clean room, temperature < 25ºC | |

| Relative humidity 50-65% | |

| Away from direct sunlight, fire, heat | |

| For best performance, use within 6 months | |

| Product Details | |

| Type | Candy Nano Chrome Rose Red Powder Coating For Steel Hanger |

| Colors | Chrome Rose Red |

| Surface Finish | Smooth |

| Gloss level | 120-150% |

| Particle Size | Average 32-42μm |

| Specific Gravity | 1.2-1.7g per cubic meter |

| Coverage | 8-10 square meters per Kg at 30-90 μm film thickness |

| film thickness | 120-150um Two Layers |

| Application Recommendation | |

| Application Voltage | 40-60 KV |

| Gun to Component Distance | 15-30CM |

| Curing Temperature | 200ºC x 10min |

| Powder coated Film Mechanical Properties | |

| Adhesion | Cross-cut(2mm),no loss of adhesion |

| Impact Resistance | Direct impact 50kg/cm |

| Pencil Hardness | 2H |

| Cupping Test | 6mm Mandrel |

| Bending Test | 5mm |

| Powder Coated Film Chemical Resistance | |

| Salt Spray Test | 5% NaCl Solution for 500 hours - No change |

| Acid Resistance | 5% HCL for 48 hours dip test - No change |

| Alkali Resistance | 5% NaOH for 48 hours dip test - No change |

| Storage Stability | |

| Store in ventilated, dry, clean room, temperature < 25ºC | |

| Relative humidity 50-65% | |

| Away from direct sunlight, fire, heat | |

| For best performance, use within 6 months | |